Electro-Optics Laboratory (EOL)

EOL

Electro-Optics Laboratory

Mission:

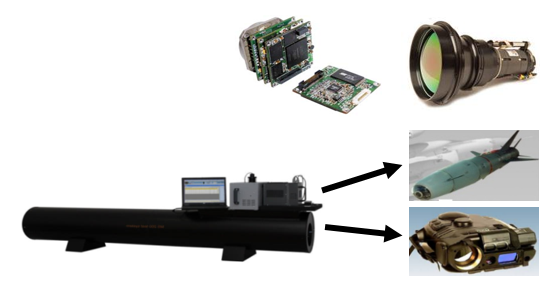

The Electro-Optics Lab was established in 1431 H (2010) with an aim to engage in design, manufacturing and testing infrared and electro-optical sensors, focal plane arrays and camera systems. The lab also aims to educate a new generation of engineers, in the above named technologies who will be the driving force for technological advancement and innovation in the Kingdom of Saudi Arabia.

Description:

Focus Areas:

In the Electro-Optics Laboratory we perform in-house design, simulation, fabrication, and characterization for our devices and systems.

The research and development activities of Electro-Optics lab are currently focused in the following areas:

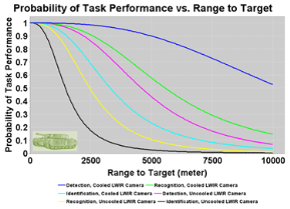

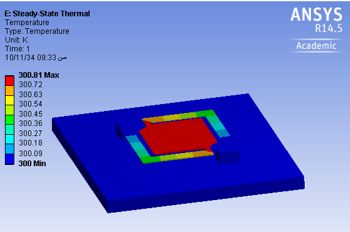

- Microbolometers for infrared and millimeter wave detection.

- Infrared and millimeter wave antennas.

- Infrared and millimeter wave sensor materials.

- Metal-insulator metal diodes.

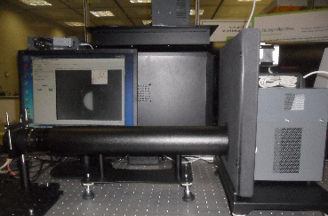

- Infrared and electro-optical imager testing.

Facilities and Equipments:

Our facilities include:

Our facilities include:

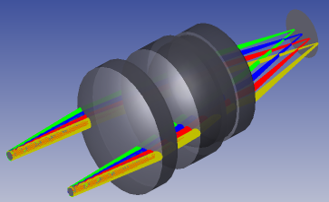

- Simulation software

- COVENTOR for MEMS simulation.

- HFSS for antenna simulation.

- Electronics

- Agilent 35670A signal analyzer (122 µHz - 102.4 kHz).

- Ametek 5210 lock-in amplifier.

- An assortment of electronic lab equipment (DC power supplies, function generators, DMM, etc.).

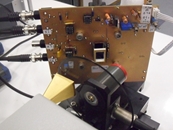

Custom-built electronics: We build in-house custom low noise circuits for sensor bias and readout.

Custom-built electronics: We build in-house custom low noise circuits for sensor bias and readout.

- Semiconductor Characterization

- Agilent B1500 semiconductor parameter analyzer with I-V and C-V measurement capabilities.

- Cascade Microtec EP6 DC parametric probe station.

- Vecco Dektak 150 surface profilometer for thin film profile measurements.

- JANDEL multiHeight four point probe.

- Sentech infrared spectroscopic ellipsometer.

- Agilent B1500 semiconductor parameter analyzer with I-V and C-V measurement capabilities.

- Micro/nano Fabrication

- A 22 m^2 softwall clean 1000 cleanroom.

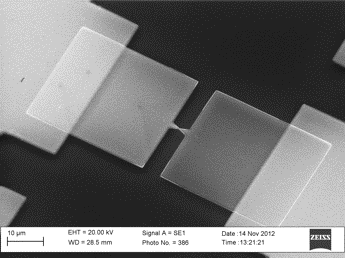

Zeiss Scanning electron microscope (SEM) with Raith Elphy Quantum nanolithography module for electron-beam lithography.

Zeiss Scanning electron microscope (SEM) with Raith Elphy Quantum nanolithography module for electron-beam lithography.- NXQ 4004 contact mask aligner for photolithography.

- AJA International magnetron sputtering system for deposition of thin metallic and non-metallic films.

- Diener Electronics reactive ion etcher and plasma asher.

- FELCON fume hood with BOE etch bath.

- Olympus MX51 semiconductor inspection microscope.

Hybond ultrasonic Wire Bonder.

Hybond ultrasonic Wire Bonder.- ATV RV129 manual wafer scriber.

- Brewer Science CEE 200 spin coater.

- Brewer Science C1300 hot plate.